Our Manufacturing Plant

Kalyani Electronics' manufacturing unit is located in Dadra Nagar Haveli (U.T.), India. It is equipped with state-of-the-art manufacturing equipment and comprehensive in-house testing facilities that comply with ISI and various international standards. Our success is driven by the high quality of our products, achieved through careful selection of raw materials and rigorous quality control at every manufacturing stage. Our dedicated technocrats have developed some of the most advanced products in the field. We prioritize continuous R&D to enhance product quality, fostering brand loyalty and company growth.

Raw Materials

Our raw materials are sourced from reputable and approved vendors across the country. Each batch is accompanied by test reports, and we conduct our own testing to verify these reports before production begins. This stringent verification process ensures that only the highest quality materials are used, contributing to the excellence and reliability of our final products.

Product Packaging

Once the product passes all quality tests, it is carefully handled and sent to the packaging section. Here, products are packed according to customer requirements, using wooden reels, corrugated boxes or coils. Our packaging process ensures that products are protected during transit, maintaining their integrity and quality until they reach the customer. This meticulous approach to packaging underscores our commitment to delivering products in perfect condition, ready for immediate use.

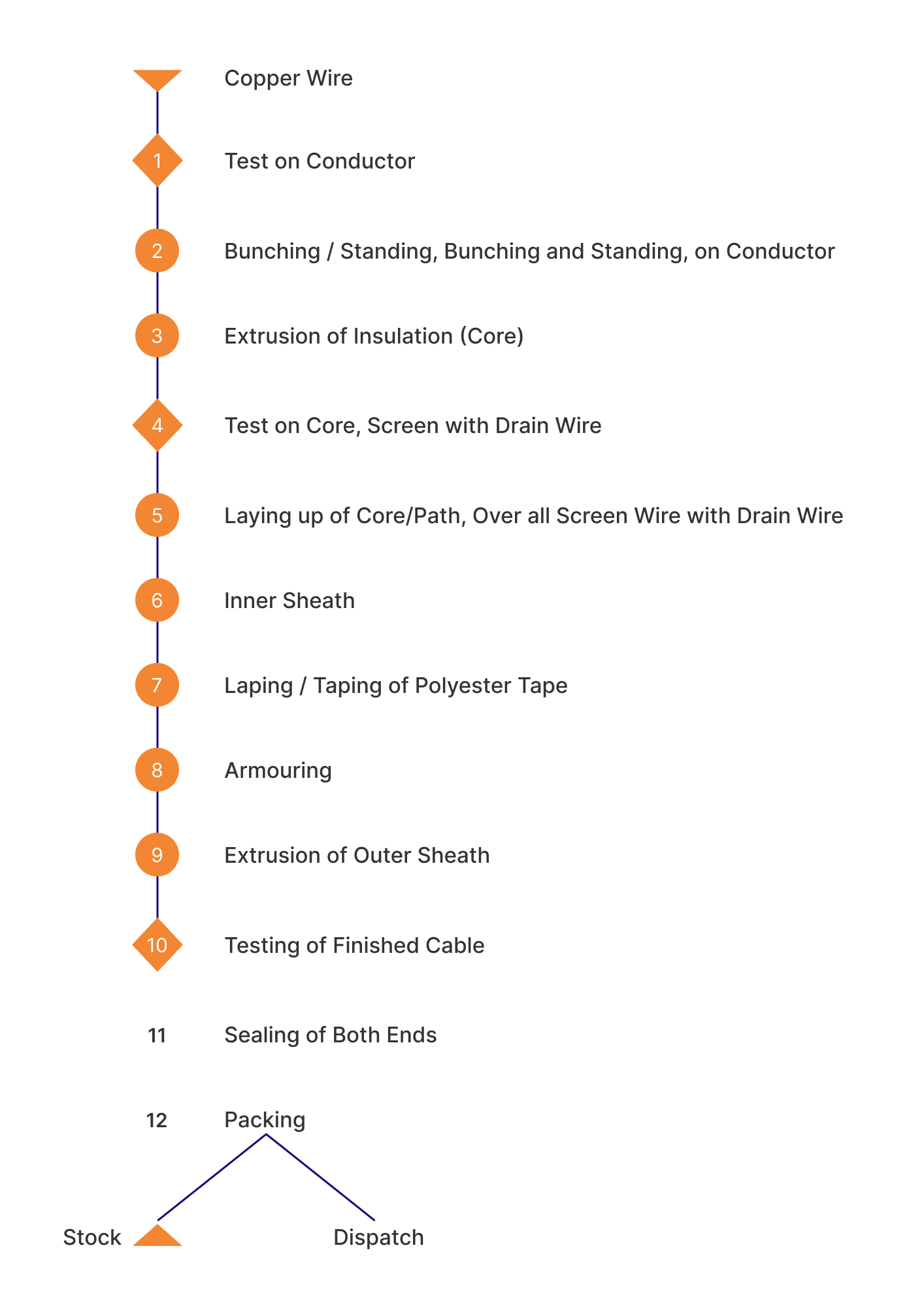

The following process chart explains the complete manufacturing and quality control process:

Machinery

Our manufacturing facility in Dadra is equipped with the latest state-of-the-art machinery to ensure superior quality and efficiency. The plant includes advanced equipment for processes such as bunching, stranding, braiding, coiling, and extrusion with water circulation. We also utilize high-speed mixer cum dryers, horizontal armoring, taping machines, cable printers, and welding & weighing machines. All machinery is regularly serviced, calibrated, and upgraded to maintain continuous high-quality production. This comprehensive in-house setup allows us to meet stringent industry standards and deliver exceptional products.

Testing

Our dedicated, air-conditioned laboratory is designed to conduct all necessary tests to meet standard certification requirements. Each batch of raw materials undergoes rigorous inspection upon receipt, ensuring only the highest quality materials enter our production process. Final product testing is conducted on a batch-wise basis, ensuring consistent quality and compliance with industry standards. Our lab is equipped with advanced testing instruments, and our stringent quality control measures guarantee the reliability and performance of our cables.